SMALL PRECISION

DIAMOND TOOLS

New Location 401 Delaware Dr. Kutztown, PA 19530

DIAMOND TOOLS

DIAMOND TOOLS

New Location 401 Delaware Dr. Kutztown, PA 19530

DIAMOND TOOLS

DIAMOND TOOLS

New Location 401 Delaware Dr. Kutztown, PA 19530

DIAMOND TOOLS

DIAMOND TOOLS

New Location 401 Delaware Dr. Kutztown, PA 19530

![]()

who we are

Over 30 Years Experience

Lammers Microdrill is a small business consisting of a core group of individuals who have over 30 years experience building and using small metal bond diamond tools. We pride ourselves on building the finest quality small tools on the market.

History

Lammers Microdrill started in the late 1980’s to fill the need for small precision diamond core drills under 1/8” in diameter in certain industries such as aerospace and medical devices. Over the past 30+ years, Lammers Microdrill expanded into various styles of small metal bond tools with a principal focus on building the toughest tools available under ½” in diameter.

Tools for Many Industries

The wide range of custom-built tools we offer allows us to serve a wide range of industries including aerospace, optics, medicine, solar, and semiconductors manufacturing. The success of the company is built on a foundation of technical ceramic machining requirements knowledge and a tried-and-true formula for building small diamond tools.

Call to order your own custom diamond drills and tools: 610-894-9502

![]()

big focus

On Small Tools

All of the tools currently built by Lammers Microdrill consist of diamond grit abrasive impregnated in a metal bond. The small size of the tool requires us to start with the best materials available and build to very strict quality standards, with tight tolerance and zero runout being the norm. We optimize diamond tools for use on the following common materials as well as many other tough-to-machine nonmetallic materials.

Use custom specialty tools on:

- Aluminas

- Quartz and Glass

- Sapphire

- Carbides such as Silicon Carbide, Boron Carbide, and Tungsten Carbide

- Zirconia

- Piezoelectric materials

- Natural stones and minerals

- YAG

- Beryllia

- Various Composite Materials

- MACOR

- Nitrides such as Aluminum Nitride, Boron Nitride, and Silicon Nitride

These tools are either sold as unmounted with just the diamond section and drill tube, or as a mounted tool based on the customer’s requirements.

Common adapter mounts include Branson, 1”-14 female, 7/8”-14 female, 3/4"-16 female, 5/8”-18 female, Belgian, and Habit.

Most common shank sizes in both brass and steel are also available for mounting. Tight tolerance centerless ground shanks can be specified when required. 5/8” OD centerless ground steel shanks for OptiPro machines also an available option.

Reach out to us and get the metal bond diamond tools you need.

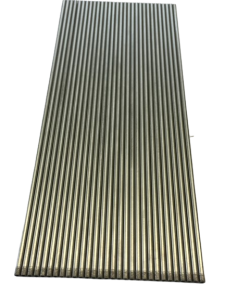

CORE DRILLS

Small high-quality metal bond core drills are the flagship product at Lammers Microdrill. Our core drills are manufactured using thin wall stainless steel tubing to minimize the wall thickness of the drill and prevent oxidation of the drill tube.

Specifications for our core drills include:

- Sizes - Sizes range from .023” OD to .475” OD.

- Inside Diameter - ID critical drills can be manufactured with .010” ID to .386” ID.

- Tolerance - Standard tolerance is ±.001” OD/ID. Our tightest tolerances are ±.00025” OD and ±.0005” ID.

- Grit & Bond - diamond grit and bond can be selected based on material and machining requirements.

- Custom Features - ID features such as waterways or flats are also available for both ID and OD drills.

Deep drilling depths

Lammers Microdrill specializes in extra-long core drills with drilling depths up to 24.”

These drills have historically been used in the manufacturing of gas laser tubes, but they can have applications in other manufacturing processes such as laboratory glassware.

Call to order your custom manufactured core drills: 610-894-9502

ROUTER TOOLS

All Lammers Microdrill router tools greater than 1/16” feature a unique hourglass slot in the face to aid in the flow of coolant and swarf removal. Hourglass slots can be placed on center for side milling or offset for plunge milling.

Coolant holes can be added to tools greater than 1/8” for pushing coolant through the tool. These tools feature a thick wall tool steel tube to withstand side pressure from milling.

Router tools with a .0225” -.050” OD are solid tools with no slot on the face.

Call to order your custom manufactured router tools: 610-894-9502

SPECIALTY TOOLS

Lammers Microdrill can make the following specialty tools under .475” OD

- Disintegrating drills with an offset coolant channel for creating blind holes with flat bottoms. These tools can be made with thick wall steel tube for milling as well as drilling.

- Small solid tools and reamers down to .023” OD commonly used for milling small pockets, removing corner radiuses, or reaming a hole to a precise size.

- Small mounted wheels with carbide shanks for ID grinding.

- Generating and radius milling tools for creating convex shapes.

- Counterbore tools with a specific OD and ID.

- Chamfer tools with an included angle ground on the face of the tool. These can be made with or without a coolant hole.

- Double drills or dual core drills commonly used for creating toroid shapes.

Contact us with your small tooling needs and let us design the best tool for the job: 610-894-9502

WATER SWIVELS

Water Swivels are used to add tool thru-coolant capabilities to machines that are not equipped with a through spindle coolant feature.

Lammers Microdrill offers a full-size water swivel as well as a “mini” water swivel for light duty applications.

Lammers manufactures water swivels using high-quality components. New units will not have any measurable runout.

Full size water swivels feature a 7/8” shank and accept a Branson mount or 5/8”- 18 female adapter.

Mini water swivels feature a 1/2” shank and accept a Branson mount or 3/8”-24 female adapter.

Call to order your custom manufactured water swivels: 610-894-9502

![]()

Contact us to order your own small metal bond diamond tools. We build to your existing specification and provide advice on how to build the best tool for your job. Lammers Microdrill also builds small specialty tools for a wide variety of industries including:

- Aerospace and defense

- Medical device manufacturing

- Optics manufacturing

- Glassware manufacturing

- Research universities

- Ferrite manufacturing

- EV and solar industries

- Semiconductor manufacturing

Address:

401 Delaware Dr.

Kutztown, PA 19530

Call: 610-894-9502